Siebe, Gorman & Co diving pump for two pearl divers

Manufacturer

Siebe, Gorman and Company Limited

(British, 1880 - 1998)

Date1905-1950

Object numberV00004225

NameAir pump

MediumWood, metal

DimensionsOverall: 1299 x 1879 x 817 mm, 300 kg

ClassificationsTableware and furnishings

Credit LineANMM Collection

DescriptionThis air pump produced by Siebe, Gorman & Co. Submarine Engineers, was used by pearl shell divers off Broome, Western Australia. Crew on board the pearling lugger would turn the two large wheels which would send air to a maximum of two divers on the sea bed below.The pump is housed in wood, with large twin pump wheels placed at either side. On the front of the housing are two nozzles which hoses connected to and supply the air to the divers. A lever located beneath the housing lid can be adjusted to allow either one or two divers to use pump. One of the nozzles is labelled 'deep water' while the other is labelled 'ordinary depths'.

The pump features twin bourdon pressure gauges, which monitor pounds of pressure (from 0 to 100 lbs) and feet of salt water (from 0 to 226 ft).

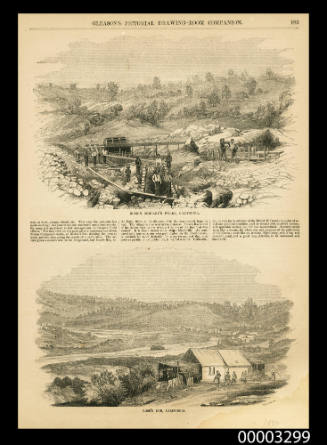

HistoryThe European-Australian pearling industry began in the 1850s and by the early 20th century, Australia was supplying 75 per cent of the world's pearl shell, from north Western Australia, the Northern Territory, and the Torres Strait. Pearl shell was a valuable material before the days of plastic, and sold for £150 per ton in Sydney in the 1860s. The versatile and decorative material was used to make buttons, buckles, jewellery and cutlery, and was used as inlay in watches, ornaments and instruments. Before the cultivation of pearls, naturally occurring pearls were rarely found and were considered a bonus.

For thousands of years, local coastal Aboriginal populations traded natural pearls with neighbouring islanders, and pearl shell - collected by combing the beach while the tide was out - with inland Aboriginal groups. With the foundation and rapid expansion of pearling stations in the 19th century, European pearlers unable or unwilling to undertake the difficult and dangerous task of diving employed cheap Japanese, Pacific and Torres Strait Islander, Philipino, Malay and Indigenous Australian labour.

Originally shallow pearl shell beds were worked on by free-diving from small open boats. The desire to access shell beds located in deeper water saw the use of hard-hat diving suits and equipment which was developed in the 1830s by Augustus Siebe and became widespread on Australian pearl luggers in the 1880s.

This standard dress diving suit consisted of a waterproof suit and airtight helmet, connected by a hose to an air pump on the pearl lugger's deck. The diver wore layers of woollen garments under the suit, along with mittens and boots weighing up to 7kg each. The heavy copper helmet with a glass face was screwed onto the corselet which was supported by the padded collar of the dress. Up to 50kg of weight was strapped onto the divers back and chest. Attached to the divers belt was a knife, scabbard and rope which was used to send signals to the crew before the application of radio communication equipment.

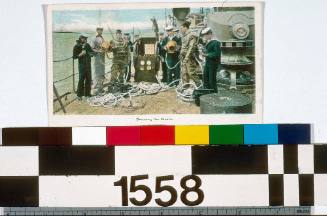

Air was pumped to the diver manually by men turning two large wheels. The equipment and system was problematic, as divers could not regulate their air flow and were only permitted small quantities of air. The development of the high pressure compressor in the 1900s and the Ohgushi Peerless Respirator in 1918, allowed divers to manually adjust their air flow with a valve.

In the early days of deep water pearl diving, it was difficult to equalise the pressure inside and outside the suit, and the little-known decompression sickness known as the 'bends' claimed the lives of hundreds of divers. The introduction of the wet-suit, mask, fins and self contained underwater breathing apparatus (SCUBA) gave divers greater manoeuvrability and better air supply, and saw a decline in pearl diving fatalities. The transition to this new equipment was slow, but as diver's productivity increased the use of hard-hat equipment by Australian pearl divers ceased in the mid 1970s.

SignificanceStill operational, this complete air pump is an example of the equipment used by pearl divers in Australian waters before the development of the self contained underwater breathing apparatus (SCUBA).

Siebe, Gorman and Company Limited

1966