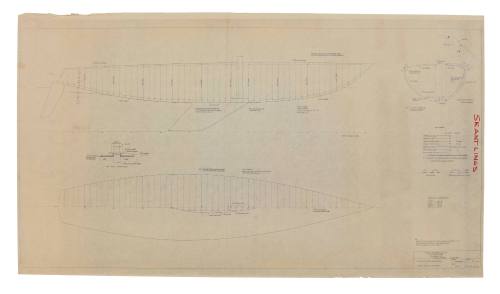

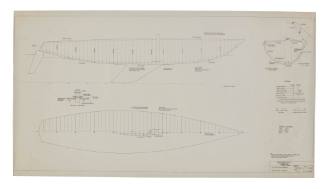

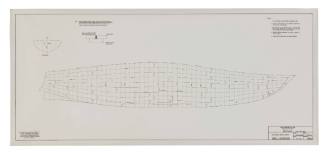

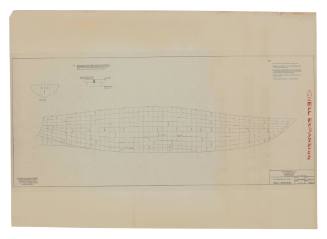

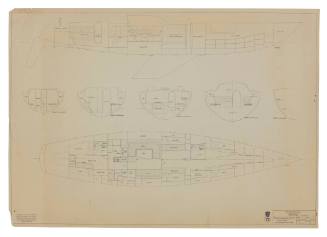

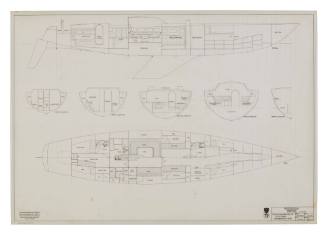

Profile and decks - scantlings for 72 foot ocean racing yacht

Designer

Ben Lexcen

(1936 - 1988)

Date3 August 1973

Object numberANMS1543[056]

NamePlan

MediumPaper

Dimensions760 x 1370

Copyright© Ben Lexcen

ClassificationsMaps, charts and plans

Credit LineAustralian National Maritime Museum Collection purchased with USA Bicentennial Gift funds

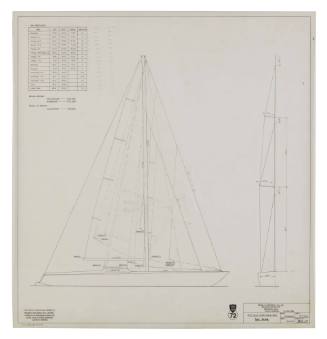

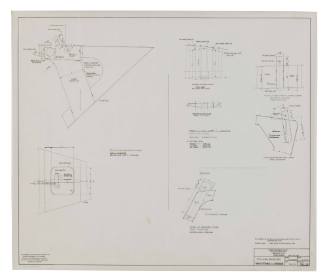

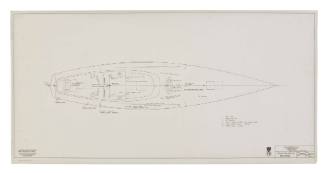

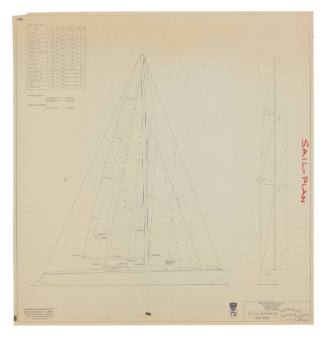

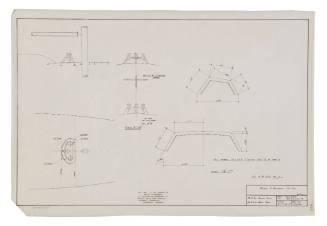

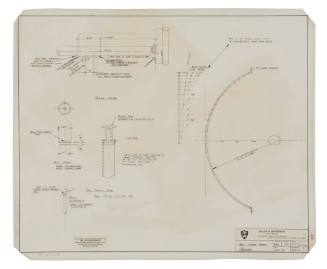

DescriptionBALLYHOO hull construction, photo-copy drawing, showing the details and materials required, to build the 72-foot maxi racer, designed by Ben Lexcen (then Bob Miller) and his team at ‘Miller & Whitworth’ in 1973.HistoryThe design work for the 72-foot aluminium maxi-racer’ BALLYHOO’ started at the ‘Miller & Whitworth’ design office in early 1973. The first drawings were the hull lines plan, then the sail and rigging plans and the interior accommodation. The owner of the yacht, Jack Rooklyn, will have been consulted and his requirements included in the design project. By August 3rd. 1973 the hull and deck construction drawings were ready, and will have been submitted to the Lloyds Classification Society office in Australia for approval, before work could start building the yacht.

During his long career as a naval architect, Ben Lexcen designed many yachts using aluminium as the build material, including the 45-foot IOR yacht APOLLO II, and all the seven 12mR America Cup challenge yachts. Marine grade aluminium is an ideal material to build large offshore racing yachts. It is light-weight and does not rust like steel, clean and easy to cut with a saw or router, while at the same time a strong material to use for yachts. Ben Lexcen (formally Bob Miller), along with his team at ‘Miller & Whitworth’, continued design work on the yacht during the build, and up to completion in November 1974 when the yacht was launched at the ’Halvorsen, Morson and Gowland’ boatyard.

The construction of most steel and aluminium sailing yachts is carried out with the hull upside down. This is to make the work easier, safer and also more accurate. With the hull upside down, all welding work is ‘down-hand’ not ‘overhead’ so will be better quality. The keel and centre line of the yacht, along with all the frames, deck beams, and floors will be cut out in the shipyard workshops. More commonly today, all the parts of a steel or aluminium yacht are cut by a CNC machine, and delivered to the build-site as a ready cut kit. The hull will likely be built using a strong jig to hold the parts in place before welding. The deck centre-line girder and deck beams may be fixed to the jig, upside down, along with the ten, hull web-frames. The keel centre girder will be fitted and tack-welded in place before the additional hull frames are fitted. When all the parts have been installed, and the hull frame-work checked for alignment, it will be fully welded before the hull plating is cut, rolled and fitted.

Jack Rooklyn named his new yacht BALLYHOO, after his Australian company, ‘Bally Gaming’. He entered the yacht in the 1974 Sydney to Hobart offshore yacht race, which started on December 26th. just over a month after the yacht was launched. It was a useful race to test the crew and new yacht, which came in sixteenth of the sixty-three starters. The first race for BALLYHOO outside Australian waters, was the1975 ‘Three Kings Islands Race’ in New Zealand. She then crossed the Pacific to the USA to take part in Trans-Pacific or ‘Transpac Race’.

Ben Lexcen (then Bob Miller) the designer, joined the yacht as watch captain for the 1,227 mile, 1975 ‘Transpac Race’, race, from the Point Fermin buoy in San Pedro, California to Diamond Head in Hawaii. BALLYHOO was the first Australian yacht ever to enter this race. Following the race, the yacht and her crew, stayed in Hawaii to compete in the annual ‘Hawaiian Island Series’. This included the ‘Round the State Race’ in which BALLYHOO lost her rudder in very bad weather. Remarkably, the crew made up, a temporary rudder using the teak saloon table and spinnaker pole. The, following a difficult 250 miles back to Honolulu in 34 hours BALLYHOO still crossed the finish line ahead of some other yachts.

Initially, BALLYHOO did not sail as well, or as fast as expected, so in late 1975 and 1976 the weights were adjusted, the ballast keel re-cast and the rudder replaced with a deeper support skeg. These changes made a significant improvement, making BALLYHOO a fast and highly successful offshore racing yacht, on all points of sailing and in all wind conditions. In 1976 Jack Rooklyn accepted an invitation from the prestigious ‘California Yacht Club’ to race BALLYHOO in the California Cup and St. Francis Perpetual Series. BALLYHOO arrived in Los Angeles in 1976 following an amazing winning streak, which started with winning the ‘South China Sea Race’. In the 1976 California Cup race BALLYHOO beat the famous America maxi yacht ‘KIALO III’. As one yacht magazine report at the time: The Australian yacht BALLYHOO proved what many already believed: she is unquestionably the fastest yacht in the world to windward. The yacht then went on to Honolulu, for the ‘Round the State Race’ again, this time taking line honours and many hours off the elapsed time record.

BALLYHOO pioneered the sloop-rig maxi, and went on to win line honours in the 1976 Sydney-Hobart race and, many other races during her career. The yacht sailed in all the major off-shore racing events in the coming years, wining line honours at the 1977 Fastnet Race in UK. BALLYHOO was sold to Bill Whitehouse-Vaux in 1978, who re-named the yacht MISTRESS QUICKLY and continued to race the yacht into the mid 1990’s. She took part in the 2001 ‘Maxi-yacht Rolex Cup Race’ in Porto Cervo, Sardinia and is believed to still be sailing today as a charter yacht.

SignificanceThe 72-foot maxi-racer, designed by Ben Lexcen (formally Bob Miller) for Jack Rooklyn in 1973, was built of marine grade aluminium alloy and built to Lloyds Rules. These construction rules provide the material type, and sizes of all the parts to be used in the construction of the hull and deck, as well as following the correct welding procedures. Marine grade aluminium is a light-weight, easy to cut, but strong material to use for an offshore racing yacht. Ben Lexcen designed many yachts using this material, including the 45-foot IOR yacht APOLLO II, and all seven 12mR America Cup challenge yachts.