Part of demand valve

Maker

Bob Lynch

Datec 1950

Object number00037616

NameDemand valve

MediumBronze

DimensionsOverall: 55 x 55 x 20 x 110 mm, 0.2 kg

ClassificationsTools and equipment

Credit LineANMM Collection Gift from Bob Lynch

DescriptionPart of a brass demand valve made by Wally Gibbons and used by Bob Lynch in the 1950s. The valve was used to equalise the air in the air tank with the pressure of the water around the diver. Gibbons took out a patent on the Cousteau - Gagnan aqualung and began to make diving equipment in Australia post 1945.

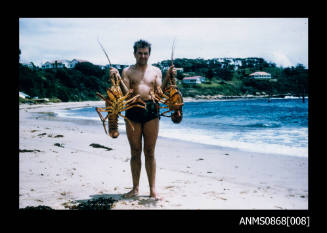

HistoryBob Lynch was a recreational diver and actively dived until 1998 whilst in his 60s. He continued to snorkel from then on, still using his diving knife and weight belt from the 1950s - 1960s.

Bob had made much of his original equipment, as there was not much available commercially in those early years.

A friend of his, Wally Gibbons, also made equipment. He had seen the Cousteau-Gagnau patent aqualung and adapted it for sale in Australia. It was Gibbons who made this demand valve used by Bob Lynch. For ease of manufacture they split the demand valve and the high-pressure valve. Bob was in his late 20s/early 30s when he bought this demand valve from Wally Gibbons .

Bob made the rest of his equipment using an Austrian oxy welding high pressure reducing valve. Air hoses were adapted from WWII gas masks and Bob made his own rings from stainless steel or brass.

Air cylinders were from WWII aircraft and contained 40 cubic ft of air. Mouth pieces

were adapted from WWII gas masks and the demand valve was worn on the chest. Air was difficult to obtain and Bob either obtained it from Wally Gibbons in North Sydney or from medical air cylinders .

Bob Lynch lived in Auburn when he began his diving at Clovelly. He usually dived on his own and was more interested in fishing rather than group dives.

When he dived he wore swimming trunks, three crew neck jumpers covered by a seal skin (a wrap on garment of rubberised fabric).The jumpers were altered to make one jumper that would cover the body to create a polo neck jumper with an extra long body. It sometimes took six jumpers to make a good diving jumper. Bob also used a Dick Charles safety belt. It was made of plastic laced at the back with straps that went over the shoulders. On the side was a container with a spark lit bulb which inflated the belt if activated. It was an early form of life belt.

Bob experimented with the Danny Wells helmet, a diving helmet customised for each diver. A plaster model of the diver's head and face was made and covered in tube dough with uncured rubber strips. This was then boiled in a kerosene tin to cure the rubber. It was trimmed and glass added to form a customised mask. It never went into commercial production as face masks became available in the 1950s.

Bob described an early diving helmet at Clovelly being made of kerosene tins.

SignificanceThis demand valve part is part of a collection belonging to Bob Lynch and represents recreational diving gear from the 1950s and 1960s, spanning both home made technology in the post war period to early commercial gear. It shows how early divers had to make their own equipment until diving gear was readily available in the 1960s .

Siebe, Gorman and Company Limited

1966

11 January 1941