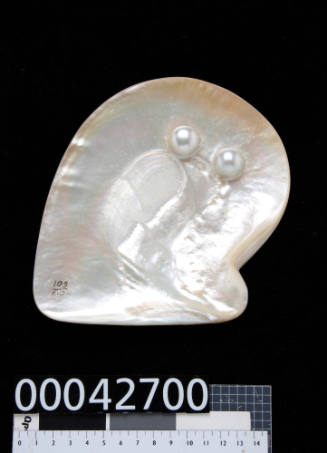

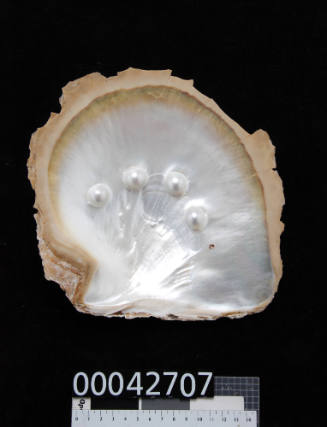

Small black pearl shell with one cultured blister pearl on the top centre of the shell

Maker

Denis George

(Australian, 1917 - 2001)

Date1957-1977

Object number00042719

NameShell with blister pearls

MediumPearl shell, cultured blister pearl

DimensionsOverall: 2 x 108 x 115 mm, 79.44 g

ClassificationsAnimals and animal products

Credit LineANMM Collection Gift from the George Family and Adrian Jackson

Terms