Marine Chronometer H1 Replica

Date2010

Object number00056183

NameChronometer

Mediumvarious metals - brass, steel; timber - lignum vitae, oak

DimensionsOverall (Approximate measurements): 700 × 770 × 510 mm

ClassificationsTools and equipment

Credit LineAustralian National Maritime Museum Collection Gift from Mr Norman Banham

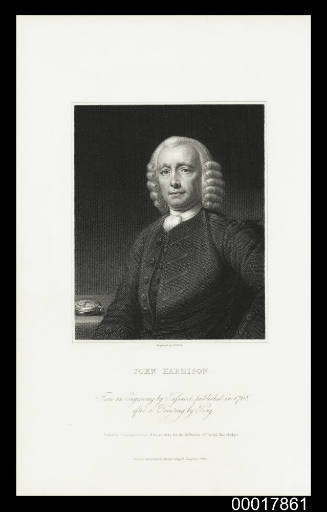

DescriptionThis remarkable replica chronometer was one of a series of four clocks made in the 2000s by retired Australian scientific instrument maker Norman Banham to replicate those created in the 18th century by British clockmaker John Harrison in his legendary quest to solve the problem of longitude.

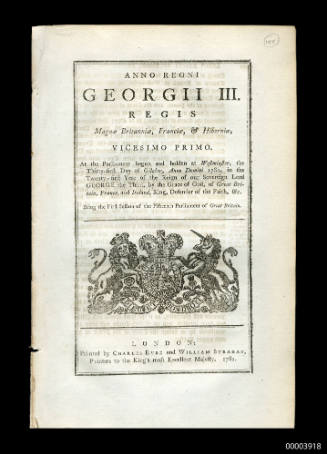

In 1714 the British Longitude Act offered a reward for those who produced a solution to calculating longitude at sea to enable navigators safe and efficient passage. Clockmaker Harrison devoted himself to a mechanical solution to timekeeping at sea, and famously battled the Board of Longitude and its influential astronomer supporters who looked exclusively to the skies for a solution.

This is Mr Norman Banham's remarkable replica of Harrison's first attempt from 1737 known as H1.

H1 is a table-based clock which filled a space 70x80x55cm, with more than 1440 moving parts of brass, with timber wheels rollers and bearings.

The front face features a dial at the top for seconds (60); on the left for minutes (60) and on the right for hours (24), while the lower dial shows the month (marking 31 days)

Harrison refined his series of five sea clocks over the course of 50 years to ultimately claim financial rewards with the proof of concept in his fourth design - the comparatively small portable sea watch, fitted in a circular housing developed by John Jefferys. This clock was reproduced by Larcum Kendall and successfully trialled on James Cook's second voyage of 1772-75 alongside chronometers by John Arnold, and astronomical observations in the lunar distance method. His fifth design allowed navigators to make adjustments by moving the hands without opening the back of the clock.

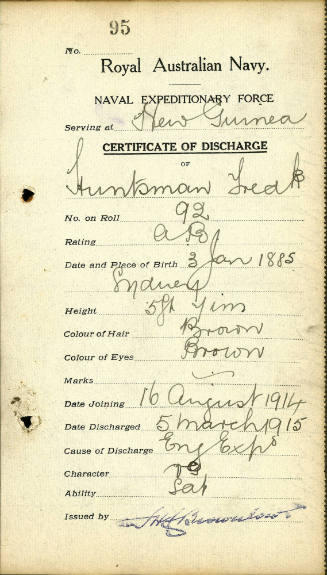

HistoryNorman Banham spent his life at Mount Stromlo Observatory, where his father established the technical workshop in the new facility in the late 1920s. After World War II the young Norman began work in the workshop and trained at Canberra technical college as a fitter and turner, because no scientific instrument maker courses were available. He retired in 1988.

In an incredible feat of problem-solving and innovation Mr Banham channelled John Harrison’s energy and tenacity over a 20 year period to fashion four working replicas of his series of clocks known as H1, H2, H3 and H4. H4 was the fourth of Harrison’s five sea watches that eventually won him rewards and recognition from the Board of Longitude.

Famously the problem of longitude had transfixed empires for hundreds of years. Ship masters were easily able to determine latitude by sighting the sun at its highest point. Longitude however relied on comparative measurements from arbitrary lines, between the time on board ship at sea and a home port, or another place of known longitude.

Keeping accurate time at sea had proved elusive given the actions of the rolling seas, fluctuations in temperature, moisture and weather over long distances across latitudes. Thousands of lives were lost from drowning when ships foundered on unexpected landforms, or from diseases such as scurvy after ship masters spent excessive time finding their way to port. Valuable cargoes too were lost.

Between the 16th and the 18th centuries the maritime nations of Spain, the Netherlands, France and Britain offered financial rewards to solve the problem while their best and brightest philosophised over potential solutions. The quest involved the giants of the astronomical sciences at the time including Galileo Galilei, Christiaan Huygens, Giovanni Domenico Cassini, Sir Isaac Newton and Edmund Halley. Cross channel rivals France and Britain both established observatories and harnessed astronomy in this quest.

A much-publicised, drawn-out ideological battle focussed on the esteemed astronomers and mathematicians who looked to the stars for a solution in observations of planets such as Jupiter and especially, as the 18th century progressed, the earth’s moon, and those who looked to mechanical timekeeping, to a sea clock as the solution.

Legendary former carpenter John Harrison was the chief protagonist of mechanical timekeeping. He began his quest in the 1720s, after the British Longitude Act was announced in 1714. As Dava Sobel wrote in her popular book 'Longitude: The True Story of a Lone Genius Who Solved the Greatest Scientific Problem of His Time' it consumed 50 years and a mammoth battle against the astronomers royal James Bradley and his successor from 1765 Nevil Maskelyne. Harrison supporters petitioned King George III and he was eventually vindicated. John Harrison was awarded £10,000 in 1765 and a further £8750 in 1773, after his fourth design was proved ‘practicable’, able to be produced by others.

Each of Harrison’s four clocks was an improvement on the other as he resolved problems of the day.

H1, his first clock of 1737 had taken him more than a decade to develop. It was nothing like the clocks or chronometers we know today or indeed that Harrison’s contemporaries had seen in the 18th century.

H1 filled a rectangular space 70 x 80 x 55cm and involved more than 1440 moving parts. It was heavy and table-based but met the challenges of keeping accurate time at sea. This design was endorsed by the Royal Society and met the conditions of the Longitude Act at sea trials but John Harrison himself suggested improvements, and continued work with seeding funding from the Longitude commissioners.

This led to 22 years of refinement and a further 20 of debate with the Board of Longitude. Harrison’s developmental models became smaller although remained heavy and box like, until 1759 when he unveiled a timepiece redesigned into an eminently more practical housing based on an enlarged pocket watch of the time, made by clockmaker John Jefferys. With completely different workings it featured a large balance wheel which beat more rapidly to combat the motion of the seas. To prove its practicality it was produced by chronometer maker Larcum Kendall and successfully trialled by James Cook on his second voyage in 1772-75, when tested against chronometers made by John Arnold, and the lunar distance method. Harrison’s fifth watch H5 involved a new design to correct the time by moving the hands without opening the back of the clock.

250 years later the ingenious machinery in Harrison’s clocks captivated Mr Norman Banham who set himself the challenge to make the clocks anew in a replica set of chronometers that demonstrated Harrison’s experimentations.

John Harrison’s innovations were masterful for the time. To combat the motion of the ship on rolling seas he first replaced the hanging pendulum of long case clocks with two ball-shaped bar balances cross-tied with balance springs top and bottom. He converted this arrangement into more practical circular balance wheels in H3.

To compensate for deviations in temperature to avoid expansion and contraction of the pendulum bar balances he designed a gridiron system of different metals (brass and steel) of different lengths that expanded and contracted in the heat or cold at different rates, correcting each other. This kept the pendulum timing consistent and accurate. He refined this system in H3 in a bimetallic strip attached on one end.

For the gear wheels, rollers and bearings the former carpenter used wood of differing characteristics - oak and lignum vitae selected and fashioned for its inherent strength but also because lignum vitae oiled itself, thereby preventing loss of accuracy due to expansion and contraction of lubricating oils, or gear failure. When Harrison could not use wood he used rust-proof brass.

His other major innovation was the low friction ‘grasshopper’ escapement which directs the energy to keep the pendulum in motion. He refined this design in H2 adding a separate secondary winding mechanism, a remontoire spring to regulate the energy to the escapement for better timekeeping.

Whereas in the 16th to 18th centuries astronomy and mechanics were at odds in twenty-first century Canberra they were effectively fused in the skills and life story of Norman Banham.

Norman Banham spent his working career and much of his early family life at the Mount Stromlo Observatory where his father Horace, a qualified scientific instrument maker at the Cambridge Instrument Company, ran the workshop. Horace had migrated from post-war England in 1923 and the next year was headhunted to work at Australia’s first observatory taking shape near the new national capital.

Norman grew up at Mount Stromlo. As a young boy he remembers watching his father silvering the mirrors of one of the telescopes with silver nitrate every 12 months to maintain its reflective qualities. When he turned 16 in 1947 the observatory switched back to peacetime astronomy and Norman left school to begin his apprenticeship in the workshop. He cycled the 10 kilometre round trip to and from Canberra technical college where he studied fitting and turning because in Australia there were no scientific instrument courses available.

29 years later Norman was leading hand, machining components and instruments from drawings from the design office and fitting, adjusting and rebalancing them on and around the large telescopes. Over the course of his 40 year career the instruments, and the work became more sophisticated with the introduction of new electronic technologies

Norman Banham retired in 1988 and became involved in the Horological Society where his interests and expertise coalesced. He became hooked on the aesthetics and motion of the Harrison clocks - their intricacy, ingenuity and the interconnectedness of components, and in particular the clever, backward forward motion of the ‘grasshopper’ escapement design. Peter Conroy, a neighbour from the Observatory design office offered his computer to source the details of the Harrison clock at Greenwich from Dava Sobel’s book on Longitude and he set to work.

Norman’s biggest challenge was locating accurate plans. This took him some time and involved assistance from visiting astronomers after approaches to Greenwich proved fruitless. Eventually he was introduced to British clockmaker Don Unwin. Unwin was an engineer at Cambridge Instrument Company, where Norman’s father Horace had worked 80 years earlier. He made a replica of H3 for the Wimpole Museum, Cambridge and generously helped Norman procure a copy of Harrison’s plans of H3 lodged at Cambridge University.

Astoundingly it was only after he completed H3 several years later and moved on to H4 that Norman realised that he had started with the most complex clock. It was the only one for which he had any detail. Norman had and still has no computer. In a remarkable feat of deduction, concentration and patience Norman Banham scaled components from plans, one photograph of the clock which included a 12inch ruler, and set to work with incredible finesse and tenacity resolving all his questions of size, scale, weight, balance calibration - making and testing each component, case by case, year by year.

Materials were less of a problem. Norman was able to source his metals - brass and steel - and his timbers - lignum vitae and oak - locally in Canberra, even if he did have to cut up the backing board from parents’ sideboard to procure the English oak.

When Norman Banham began making the replica H4 several years later the British Horological institute had published Nevil Maskelyn’s 18th century documentation of H4 but he says he found it difficult to read old English. It did include some of the design detail required. Rather than using silver as in the original he made the case in aircraft specification aluminium.

Norman Banham’s home workshop is a magical place of muted light, shiny jewel-like machinery, pendulums, wheels, and a mesmerising soundtrack of clocks ticking, marking time in movements that see Norman moving in time to the metronome.

Norman Banham continues working on Harrison’s clocks, musing over and solving problems. He is working on the long case clock which consumed Harrison until his death in 1776. He is also working on H2. When Norman crafted the replica H2 he again turned to his ruler, pencil and paper to scale from published photographs and produced a magnificent working replica. In between then and now the Curator of horology at Royal Museums Greenwich Jonathan Betts published the detailed plans and photographs of all Harrison clocks. It was a little late for Norman because he had finished his four clocks but he realised that he had made a minute error in the size of the gear wheel. So with his gentle and enduring patience he took the entire clock apart and replaced the gear wheel. This minute change has led to many, many hours recalibrating the remontoire system, and checking all other components.

Norman Banham’s incredible working replicas are a testament to his skill as a scientific instrument maker, and to the impact British clockmaker John Harrison had on the development of timekeeping at sea, to the links between astronomy and timekeeping, between the Royal Observatory at Greenwich and Mount Stromlo Observatory outside Australia’s national capital, and between curious minds across the centuries in England and Australia in solving problems of and about the seas.

SignificanceNorman Banham's 2003 working replica of John Harrison's first sea clock of 1737 is an extremely intricate testament to the 18th century clockmaker's expertise, to his contribution to the development of European and western navigational science, and to his impact on the technology of wayfinding at sea. Banham's replica H1 is a remarkable piece of technology and an incredible achievement by the retired Australian scientific instrument maker from Mount Stromlo Observatory who trained as fitter and turner and in retirement set himself the task to replicate the results of Harrison's experimentations in four working sea clocks. It includes Harrison's major innovations - bar-bell balances mounted on anti-friction arms with temperature compensation gridirons controlling the balance springs; the use of self-oiling lignum vitae palletts to decrease friction, and the low friction 'grasshopper' escapement to direct energy to keep the pendulum in motion.

This is the first in the experimental sequence from Harrison, and the third of his clocks reproduced by Norman Banham largely without plans, from calculations made in pencil and ruler from photographs in a similarly impressive and tenacious feat of problem solving nearly three centuries after Harrison.

This replica H1 is one of a set of four, and is significant as the only set in the world made by one individual.

1700-1752