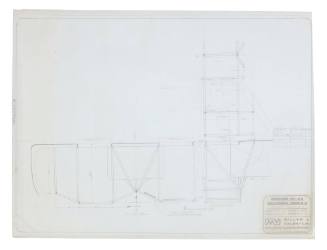

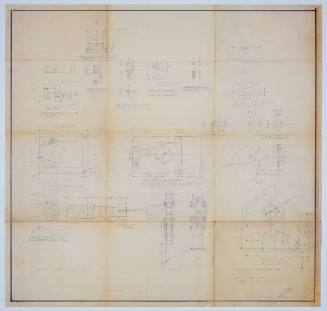

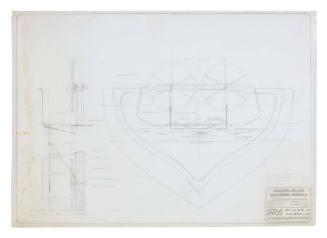

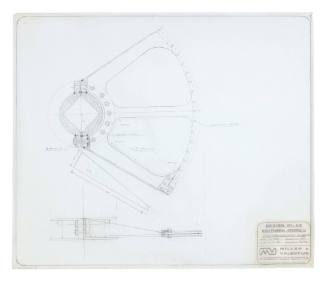

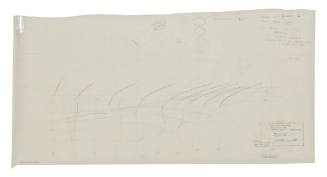

Mainsheet winch for AUSTRALIA II from Barlow Winches

Designer

Ben Lexcen

(1936 - 1988)

Date1981

Object numberANMS1543[335]

NamePlan

MediumPaper

Copyright© Robin Gillis

ClassificationsMaps, charts and plans

Credit LineAustralian National Maritime Museum Collection purchased with USA Bicentennial Gift funds

DescriptionThe 10-inch, self-tailing mainsheet winch by Barlow Marine, fitted to the 12mR challenge yacht AUSTRALIA for the 1980 America’s Cup races and likely installed on the 1983 winning yacht AUSTRALIA II HistoryThe modern deck winch, found on all sailing yachts today, developed in order to reduce the number of crew on board and allow larger sails to be used and controlled with less power. The use of blocks, on sailing ships, boats, and on-shore, has a long and rich history for the last two millennium, and still in use. By using blocks and tackle, (pulley wheels and ropes), a significant ‘mechanical advantage’ is obtained allowing heavy loads to lifted or moved, by one or two people. It can be a single, double or triple block, with the sheaves (pulley wheels) made in wood, metal or plastic, and the ‘cheeks’ which hold them made in the same material. The block is still widely used on the main-sheets of smaller yachts, where a double or triple block and rope allows the crew to easily adjust the mainsail. During the great age of sail, blocks and ropes were made and used in vast numbers. A large sailing ship in the mid-19th. Century would need over 1,200 blocks to operate. Many traditional sailing vessels still use blocks and tackles to raise and adjust their sails. This included the early racing yachts, which used very large crews to operate. The ‘windlass’, a simple vertical or horizontal rotating drum, was often used to raise sails as well as the anchor, but was not geared so relied on muscle power alone.

The first yacht to be fitted with modern, specifically designed deck winches to raise and adjust the sails, was RELIENCE the 1903 American defender of the America’s Cup. The yacht, designed by Nathanael G. Herreshoff, had the winches located below deck, while other racing yachts at the time used old fashioned deck mounted windlasses. Despite the added technology, a crew of sixty-four was still needed for racing this 120-foot yacht. RELIENCE carried a total of 1,501 square metres of sail, the same as eight later 12mR yachts. The winches proved to be both efficient and robust, as they were later used on RESOLUTE in 1920 and ENTERPRISE the 120-foot America’s Cup yacht in 1930.

Innovative Australian Malcolm Barlow first started designing and building BARLOW winches in a small garage in Sydney in the mid 1960’s. They quickly became well-known for their strong construction and fine workmanship. Barlow winches were fitted to many production yachts around the world. In America, BARIENT winches developed at about the same time and both companies seem to have worked together, as the parts, designs and tooling appears to be the same. Barient Marine was started by the owners of two yachts, Derek Baylis who owned ORIENT and Jim Michael owner of the yacht BARUNA, hence the name BARIENT.

The first self-tailing winch for use on a yacht was invented, and patented by Maurice G. Declercq, on October 26th 1973. It consisted of a separate, spring-loaded wheel, which held the rope on the winched drum. There is no information if this was produced. The now standard ‘self-tailing winch’ with spring loaded jaws, was invented by Jesus Guangorena, of the ’Barient Company’, and the patent filed on April 15th. 1975. Both Barlow in Australia and Barient in the US, produced a range of standard and self-tailing winches.

Barlow Marine in Australia also filed several patents for winches and parts: Notably on February 21st. 1979, invented by Raymond J. Porter; A self-tailing winch of the type having a stationary frame and a rotatable drum. The tail of the rope or sheet is held in a groove between a pair of toroidal shaped gripping diaphragms of elastomeric material. Also, on June 13th. 1978 an invention by; Albert J. Hutton, Allen W. Hutton and Richard J. Dellit; A variable speed winch, including a uni-directional drum rotatable initially by the clockwise motion of a handle in a clockwise sense only.

The halyard and sheet winches fitted on a 12mR International Americas Cup yacht such as AUSTRALIA, needed to be both strong and reliable. The failure of a sheet winch will almost certainly result in the yacht losing the race. The Barlow grinder winches made for AUSTRALIA in 1974 were cast in manganese bronze and likely purpose designed for the yacht. It is possible Ben Lexcen and his engineer designers may have been involved, but they would certainly have supplied information to the Barlow Company.

Both ‘Barlow Marine’ in Australia and ‘Barient Marine’ in the USA closed for business in the late 1980’s or early 1990’s, after they were bought out by rival company ‘Lewmar Marine’. However, some of the original staff at Barlow Australia bought the mould tooling and formed The Australian Winch Company which continues today. They still produce the famous HUTTON yacht winches and spare parts for Barlow and Barient.SignificanceThe fine workmanship from Barlow Marine is clearly indicated on this detailed design work for the chain driven, 10-inch self-tailing main sheet winch. Viewed together with the six attachments, and considering the dates shown on them, indicate the Barlow mainsheet winch fitted the 12mR AUSTRALIA was very likely also installed on the 1983 challenge yacht AUSTRALIA II.